Environmental Laboratory

We carry out any kind of environmental testing.

We test your development samples, prototypes and series products according to national and international standards and regulations. In our test laboratory, which is accredited according to DIN EN ISO / IEC 17025:2018, we test your products with climatic, mechanical-dynamic, corrosive, electrical and combined tests as well as with long-term tests.

Technical

test support

Flexible

Competent

Knowledge

of standards

Test methods

We carry out environmental tests on materials, components, assemblies, prototypes and series equipment across all industries. We test for customers in all industrial sectors, including the electrical industry, energy industry, automotive industry, aerospace industry, railway technology, shipping, commercial vehicle industry, defence technology and medical technology.

We simulate extreme climatic conditions through exposure to temperature, humidity, heat, thermal shock and solar radiation. We carry out corrosion tests with salt spray and harmful gases as well as mechanical-dynamic tests with vibration and shock tests.

Flexibility is our strength. Based on our flexible accreditation, we develop individual test procedures that meet your specific requirements. We provide comprehensive advice on the development of complex and customised test and trial plans.

Temperature tests

Cold tests down to -70 °C and heat tests up to 300 °C - we simulate a wide range of temperature conditions. This includes temperature changes up to 8 K/min as well as temperature shock tests in the variants air-air, air-water and splash water.

Climate tests

We test the effects of different climatic conditions on your product. RST examines the influence of high humidity or damp heat (constant and cyclic) and low pressure. We also offer climate change tests and condensation tests (constant and cyclical).

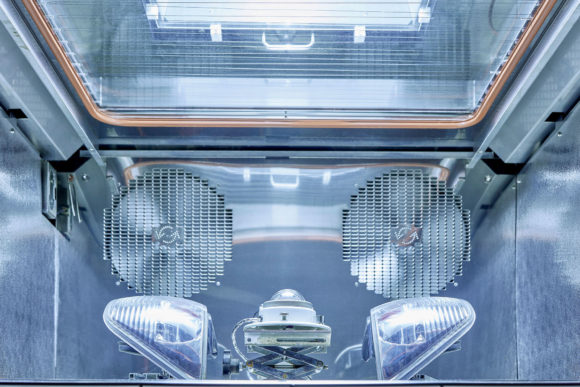

Sun simulation tests

We carry out sun simulation tests for you with metal halide lamps and xenon lamps. We also offer this test as a weathering test with superimposed sprinkling.

Corrosion tests

We carry out salt spray tests with neutral NaCl solution, acetic acid salt spray tests and salt spray with modified test solutions. RST carries out harmful gas tests with hydrogen sulphide and sulphur dioxide. Furthermore, we implement condensation water tests with sulphurous atmosphere as well as three- and four-gas tests.

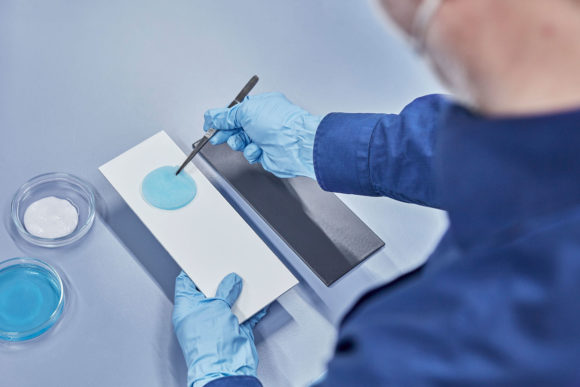

Tests for chemical resistance

We offer temperature superimposed chemical resistance tests. Various application types are available for the chemical tests. We test for resistance to reference oils as well as reference fuels, among other things.

Vibration and shock tests

We offer a range of mechanical-dynamic tests, if required also temperature or climate superimposed. These include sinusoidal vibration tests and vibration tests with broadband random, resonance tests, resonance dwells, shock tests and drop tests. Furthermore, RST develops test frames using CAD and FEM simulation and manufactures test frames with in-house CNC material processing.

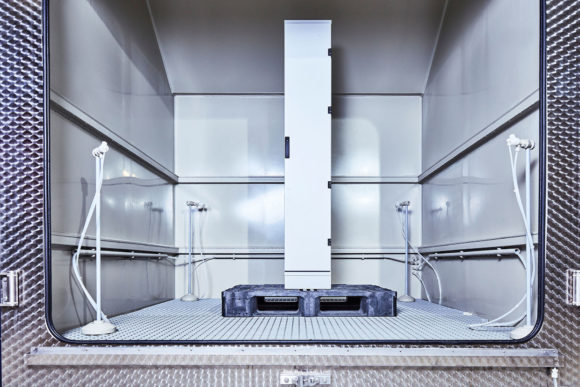

Protection class tests

We carry out IP protection class tests for many industries and applications according to IEC 60529 and ISO 20653. In our accredited test laboratory, we test your product for dust protection, contact protection, foreign body protection and water protection. RST also carries out impact and shock resistance tests (IK tests) in accordance with IEC 62262.

Electrical tests

We carry out insulation tests such as withstand voltage tests, insulation measurements and partial discharge measurements. Our range of services also includes low-resistance measurements (4-wire measurement) and contact monitoring.

Individual tests

We can also support you in individual questions beyond the standard specifications. We develop the necessary hardware and software applications for monitoring and evaluating tests and set them up at your premises.

Exactly what you need.

RST is your competent partner for the test you need

Purchasing

Our optimised processes guarantee you fast and smooth processing of your order without long waiting times. Your request is our top priority. Our wealth of experience is based on countless test orders successfully completed for a wide range of customers. Our in-house test frame production as well as our in-house calibration laboratory guarantee the highest flexibility and cost efficiency.

Project management

With our professional support, we are always at your side - even in the event of unexpected changes to the planned test sequence, necessary rework and adjustments to the test specimen as well as under deadline. During the ongoing test, you can rely on optimal communication with our testers and engineers. We always keep you up to date and contact you quickly in case of problems or damage to the test object. You are welcome to accompany your tests personally on site or via video transmission.

Quality management

RST is available to you as an accredited laboratory. Our competent and experienced test staff, equipped with comprehensive knowledge of standards and test requirements, are prepared for any challenge. Within the framework of our flexible accreditation, we develop individual test procedures for you outside of the standard specifications and are available to advise you the entire time. We deliver high-quality test reports in German and English.

The standard you are looking for?

We test for you!

STANDARD SEARCH

Lifespan testing

| VW 80000 | Electrical and electronic components in motor vehicles – Environmental requirements and tests L-01 Mechanical/hydraulic endurance test L-02 Life test, high temperature endurance run L-03 Service life test Temperature cycle endurance test |

| MBN 10306 | Electrical and electronic components in motor vehicles – Environmental requirements and tests L-01 Mechanical/hydraulic endurance test L-02 Life test, high temperature endurance run L-03 Service life test Temperature cycle endurance test |

| BWW GS 95024-3-1 | Electrical and electronic components in motor vehicles – Environmental requirements and tests L-01 Mechanical/hydraulic endurance test L-02 Life test, high temperature endurance run L-03 Service life test Temperature cycle endurance test |

Color rating

| DIN EN ISO 3668 | Coating Materials – Visual comparison of the color of coatings |

| DIN EN ISO 11664-4 | Colorimetry – Part 4: CIE 1976 L*a*b* color space |

| DIN EN ISO 2813 | Coating materials, determination of gloss value at 20°, 60° and 85° |

| DIN EN 20105-A02 | Textiles – Color fastness tests – Part A02: Gray scale for assessing color change |

| DIN EN ISO 105-A05 | Textiles – Color fastness tests – Part A05: Instrumental assessment of color change to determine the gray scale number |

| DIN 53236 | testing of colorants; Measuring and evaluation conditions for determining color differences in paints, similar coatings and plastics |

Layer thickness measurement

| DIN EN ISO 2808 | Coating materials – Determination of layer thickness 5.4.5 Method B – wedge cut (Paintborer 518) 5.5.6 Method 7B.2 – Magnetic field change, magneto-inductive method 5.5.7 Method 7C – Eddy Current |

Mechanical stress

| TD-000-0000-4033 | Factory standard Alstom TRS cleaning SJ250 5.2 testing of stability against cleaning / graffitti removing agents |

| DIN EN ISO 2409 | Coating materials – cross-cut test |

| DIN EN ISO 105-B10 | Coating materials – cross-cut test |

Electrical tests

| DIN EN 62271-1, VDE 0671-1 | High-voltage switchgear and switchgear – Part 1: Common provisions for alternating current switchgear and switchgear Section 7.7 Checking the degree of protection Section 7.10 Additional tests on auxiliary and control circuits |

| DIN EN IEC 62271-100, VDE 0671-100 | High-voltage switchgear and switchgear – Part 100: AC circuit breakers Section 6.7 Checking the level of protection Section 6.10 Additional tests on auxiliary and control circuits Section 6.101 Mechanical and Climatic Tests |

| DIN EN IEC 62271-102, VDE 0671-102 | High-voltage switchgear and switchgear – Part 102: AC circuit breakers and earthing switches Section 7.7 Checking the level of protection Section 7.10 Additional tests on auxiliary and control circuits Section 7.102 Testing of functionality and mechanical life Section 7.103 Shifting under heavy icing conditions Section 7.105 Tests to prove the correct functioning of the switching position indicator) |

| DIN EN IEC 62271-103, VDE 0671-103 | High-voltage switching devices and switchgear – Part 103: Load switches for rated voltages above 1 kV up to and including 52 kV Section 6.7 Checking the level of protection Section 6.10 Additional tests on auxiliary and control circuits Section 6.102 Mechanical and Climatic Tests |

| DIN EN 62271-105, VDE 0671-105 | High-voltage switching devices and switchgear – Part 105: AC load switch-fuse combinations for rated voltages above 1 kV up to and including 52 kV Section 6.7 Checking the level of protection Section 6.10 Additional tests on auxiliary and control circuits Section 6.102 Mechanical Functional Tests Section 6.103 Mechanical shock tests on fuses |

| DIN EN 62271-200, VDE 0671-200 | High-voltage switchgear and switchgear – Part 200: Metal-encapsulated alternating current switchgear for rated voltages above 1 kV up to and including 52 kV Section 6.7 Checking the level of protection Section 6.10 Additional tests on auxiliary and control circuits Section 6.102 Mechanical Functional Tests Section 6.103 Mechanical shock tests on fuses |

| DIN EN 62208, VDE 0660-511 | Empty enclosures for low-voltage switchgear assemblies – General requirements (point 9 only) |

| DIN IEC 60060-1, VDE 0432- 1 | High-voltage testing technology – Part 1: General specifications and test conditions (only points 4.3.5 and 5.3) |

| DIN EN 60512-3-1 | Connectors for electronic devices – Measurement and testing methods – Part 3-1: Insulation tests; Test 3a: Insulation resistance |

| DIN EN 60270, VDE 0434 | High-voltage testing technology – partial discharge measurements (VDE guideline) |

| DIN VDE 0110-20 | Insulation coordination for electrical equipment in low-voltage systems – partial discharge tests – application guidelines |

| DIN EN 60243-1, VDE 0303-21 | Electrical dielectric strength of insulating materials – Test methods – Part 1: Tests at technical frequencies |

| DIN EN 60243-2, VDE 0303-22 | Electrical dielectric strength of insulating materials – Test methods – Part 2: Additional requirements for direct voltage tests |

Xenon weathering

| VW PV 1303 | Non-metallic materials, exposure testing for vehicle interior components |

| DIN EN ISO 4892-2 | Plastics – Artificial irradiation or weathering in devices – Part 2: Xenon arc lamps |

| DIN EN ISO 105-B04 | Textiles – Color fastness tests – Part B04: Color fastness to artificial ventilation: xenon arc light |

| DIN EN ISO 105-B10 | Textiles – Color fastness tests – Part B10: Artificial weathering – Exposure to filtered xenon arc radiation |

| DIN EN ISO 30013 | Rubber and plastic tubing – Methods of irradiation with laboratory light sources – Determination of changes in color, appearance and other physical properties 6.2 Xenon arc lamps |

| DIN EN ISO 16474-2 | Coating materials – Artificial irradiation or weathering in devices – Part 2: Xenon arc lamps |

| ISO 16750-4 | Road vehicles – Environmental conditions and testing for electrical and electronic equipment – Part 4: Climatic stresses |

| DIN EN IEC 61914, VDE 0604-202 | Cable holder for electrical installations 11.1 UV resistance |

Chemical resistance

| BMW GS 95024-3-1 | Electrical and electronic components in motor vehicles – Environmental requirements and testing C-01 Chemical Resistance |

| DIN EN 60068-2-45 | Basic environmental testing procedures; part 2-45: tests; test Xa and guidance: immersion in cleaning solvents |

| DIN EN 60068-2-74, VDE 0468-2-74 | Environmental testing – Part 2-74: Tests – Test Xc: Fluid contamination |

| DIN EN ISO 2812-1 | Paints and varnishes – Determination of resistance to liquids – Part 1: Immersion in liquids other than water |

| DIN EN ISO 2812-2 | Paints and varnishes – Determination of resistance to liquids – Part 2: Water immersion method |

| ISO 16750-5 | Road vehicles – Environmental conditions and testing for electrical and electronic equipment – Part 5: Chemical loads |

| JDQ201 | Testing of Electronic and Electrical Devices — Environmental and Mechanical Loads |

| MIL-STD-810 H | ENVIRONMENTAL ENGINEERING CONSIDERATIONS AND LABORATORY TESTS Method 504.3 Contermination by Fluids |

| RTCA DO-160G | Environmental Conditions and Test Procedures for Airborne Equiment Section11: Fluids Susceptibility |

| VW80000 | Chemical Resistance C-01 Chemische Prüfungen |

| MBN 10306 | Electrical and electronic components in motor vehicles – Environmental requirements and testing C-01 Chemical Tests |

| TD-000-0000-4033 | Factory standard Alstom TRS cleaning SJ250 5.1 testing of removability of graffiti (exterior & interior) |

Temperature Tests

IEC 60068-2-1, VDE 0468-2-1 | Environmental testing – Part 2-1: Tests – Test A: Cold (Test Ab, Ad, Ae) |

IEC 60068-2-2, VDE 0468-2-2 | Environmental testing – Part 2-2: Tests – Test B: Dry heat (Test Bb, Bd, Be) |

IEC 60068-2-14, VDE 0468-2-14 | Environmental testing – Part 2-14: Tests – Test N: Change of temperature (Test Na, Nb) |

| DIN EN 50155 | Railway applications – Rolling stock – Electronic equipment |

| MIL-STD 810 H | Method 501.7 High Temperature (Storage and Operation) |

| MIL-STD 810 H | Method 502.7 Low Temperature (Storage and Operation) |

| MIL-STD 810 H | Method 503.7Temperature Shock |

| RTCA DO160G | Environmental Conditions and Test Procedures for Airborne Equiment Section 4: Temperature and Altitude Section 5: Temperature and Variation |

| VW 80000 | Electrical and electronic components in motor vehicles up to 3.5 t – General requirements, test conditions and tests K-02 Incremental Temperature Test K-03 Low Temperature (Operation) K-04 Repainting temperature K-05 Temperature Shock (component) K-12 Temperature Shock with Splash Water K-13 Temperature Shock by Imersion K-16 Temperature Shock (without enclousre)

|

| MBN 55555-4 | Non-metallic materials, material systems and semi-finished products Part 4: Thermal tests |

| DIN EN 60068-2-41 | Environmental testing – Part 2: Tests; Examination Z/BM: Combined examination; Dry heat/low air pressure |

| VW 44045 | Polypropylene, prefabricated parts 4.8 Thermal behavior 4.9 Cold behavior 4.11 Aging resistance |

| VW 50134 | PA6 for finished parts outside the vehicle interior 4.5 I 7.4 Thermal behavior 4.6 I 7.5 Cold behavior |

| VW 50133 | PA66 for finished parts outside the vehicle interior 4.1 I 7.1 Workmanship quality 4.4 I 7.4 Thermal behavior 4.5 I 7.5 Cold behavior |

| MBN 10306 | Electrical and electronic components in motor vehicles – Environmental requirements and testing K-01 high/low temperature storage K-02 step temperature test K-03 Low temperature operation K-04 Repainting temperature K-05 Temperature shock (component) K-12 temperature shock with splash water K-13 temperature shock diving K-16 temperature shock (without housing) |

| DIN EN 50125-1 | Railway applications, environmental conditions for operating resources, Part 1: Operating resources on railway vehicles 4.3 Temperature |

| MIL-DTL-7989C | COVERS, LIGHT – TRANSMITTING, FOR AERONAUTICAL LIGHTS, GENERAL SPECIFICATION FOR 4.4.5.2 Temperature shock |

| BWW GS 95024-3-1 | Electrical and electronic components in motor vehicles – Environmental requirements and testing K-01 high/low temperature storage K-02 step temperature test K-03 Low temperature operation K-04 Repainting temperature K-05 Temperature shock (component) K-12 temperature shock with splash water K-13 temperature shock diving K-16 temperature shock (without housing) |

| DIN EN IEC 61914, VDE 0604-202 | Cable holder for electrical installations 9.2 Impact test 9.3.1 (Variant A) Test with lateral loading for cable holders 9.3.1 (Variant C) Test with lateral loading for cable holders 9.4 Test with axial load |

Climate Tests

DIN EN 60068-2-30, VDE 0468-2-30 | Environmental testing – Part 2-30: Tests – Test Db: Damp heat, cyclic (Test Db40, Db55) |

DIN EN IEC 60068-2-38, VDE 0468-2-38 | Environmental testing – Part 2-38: Tests: Composite temperature/humidity cyclic test (Test Z/AD) |

DIN EN 60068-2-78, VDE 0468-2-78 | Environmental testing – Part 2-78: Tests – Test Cab: Damp heat, steady state |

| DIN EN 50155 | Climate test according to railway standard |

| DIN EN IEC 60068-2-13, VDE 0468-2-13 | Environmental testing – Part 2-13: Tests; test M: Low air pressure |

| MIL-STD 810 H | Method 500.6 Low Air Pressure |

| MIL-STD 810 H | Method 507.6 Moisture Testing |

| RTCA DO160G | Environmental Conditions and Test Procedures for Airborne Equiment Section 6: Humidity |

| VW 80000 | Electrical and electronic components in motor vehicles up to 3.5 t – General requirements, test conditions and tests K-08 Damp Heat, cyclic K-09 Damp Heat, cyclic (with freezing) K-14 Damp Heat, steady state K-19 Climatic test for components with watertight housings |

| DIN EN 60068-2-67, VDE 0468-2-67 | Environmental testing Part 2-67: Tests; Test Cy: Moist heat, constant, accelerated test, preferably for components |

| VW PV 1209 | Attachments with a zinc or zinc alloy coating and aluminum components (e.g. heat exchanger, refrigerant pipe) – corrosion test (climate corrosion cycle test) |

| DIN EN ISO 9142 | adhesives; Selection guidelines for laboratory aging conditions for testing adhesive bonds |

| BMW PR 303.5 | Climate change test for equipment parts |

| VW PV 1200 | Vehicle parts – Testing resistance to climate change (+80/- 40 °C) |

| MBN 10306 | Electrical and electronic components in motor vehicles – Environmental requirements and testing K-08 Moist heat, cyclic K-09 Moist heat, cyclic (with frost) K-14 Humid heat, constant |

| DIN EN 50125-1 | Railway applications, environmental conditions for operating resources, Part 1: Operating resources on railway vehicles 4.4 Humidity 4.6 Rain 4.8 Ice |

| BWW GS 95024-3-1 | Electrical and electronic components in motor vehicles – Environmental requirements and testing K-08 Moist heat, cyclic K-09 Moist heat, cyclic (with frost) K-14 Humid heat, constant |

| DVS 1618 Klima | Elastic thick-film bonding in rail vehicle construction, appendix 3 point 3.5 |

| DIN EN 50125-1 | Railway applications, environmental conditions for operating resources, Part 1: Operating resources on railway vehicles 4.2 Altitude 4.5 Air Movement 4.11 Pollution |

Shock- and Vibration Tests

DIN EN 60068-2-6, VDE 0468-2-6 | Environmental testing – Part 2-6: Tests – Test Fc: Vibration (sinusoidal) |

DIN EN 60068-2-27, VDE 0468-2-27 | Environmental testing – Part 2-27: Tests – Test Ea and guidance: Shock (Test Ea) |

DIN EN 60068-2-64, VDE 0468-2-64 | Environmental testing – Part 2-64: Tests – Test Fh: Vibration, broadband random and guidance (Test Fh) |

DIN EN 61373, VDE 0115-106 | Railway applications – Rolling stock equipment – Shock and vibration tests |

| MIL-STD 810 H | Method 514.8 Vibration |

| MIL-STD 810 H | Method 516.8 Shock |

| RTCA DO160G | Environmental Conditions and Test Procedures for Airborne Equiment Section 7: Operational Shocks and Crash Safety Section 8: Vibration |

| VW 80000 | Electrical and electronic components in motor vehicles up to 3.5 t – General requirements, test conditions and tests M-01 Drop M-04 Vibration M-05 Shock Test M-06 Shock Test (permanent) |

| JDQ201 | Testing of Electronic and Electrical Devices – Environmental and Mechanical Loads |

| Vibration testing with climate overlay | |

| Resonance Search / Sine Sweep | |

| Resonance Dwell / Sine Dwell | |

| Voltage Withstand Test | |

| DIN EN 60068-2-53, VDE 0468-2-53 | Environmental influences – Part 2-53: Test method tests and guidelines – combined climatic (temperature7humidity) and dynamic (vibration/shock) tests |

| DIN EN 60068-2-80 | Environmental influences – Part 2-80: Test procedures – Test Fi: Mixed-mode vibration test |

| DIN EN 60255-21-1 | Electrical relays – Part 21: Vibration, shock, continuous shock and earthquake tests on measuring relays and protective devices; Main section 1: Vibration test (sinusoidal) |

| DIN EN 60255-21-2 | Electrical relays – Part 21: Vibration, shock, continuous shock and earthquake tests on measuring relays and protective devices; Main section 2: Shock and continuous shock tests |

| DIN EN 60255-21-3 | Electrical relays – Part 21: Vibration, shock, continuous shock and earthquake tests on measuring relays and protective devices; Main Section 3: Earthquake Tests |

| DIN ISO 9022-3 | Optics and Photonics – Environmental Testing Methods – Part 3: Mechanical Stress |

| DIN EN 60068-2-57, VDE 0468-2-57 | Environmental influences – Part 2-57: Tests – Test Ff: Oscillation – Time history method and sine pulses |

| ASTM D 999 | Standard Test Methods for Vibration Testing of Shipping Containers |

| BMW PR 309.2 | Vibration testing for equipment parts Points 2.3 and 4.3 |

| VW 80200-2 | Qualification of body parts |

| DIN EN ISO 13355 | Packaging – Ready-to-ship packages and loading units – Vibration test with vertical noise-shaped excitation |

| MBN 10306 | Electrical and electronic components in motor vehicles – Environmental requirements and testing M-01 Free Fall M-04 vibration test M-05 Mechanical shock M-06 Mechanical continuous shock |

| ISO 16750-3 | Road vehicles – Environmental conditions and testing for electrical and electronic equipment – Part 3: Mechanical stresses 4.1 Vibration 4.2 Mechanical shock 4.3 Free fall |

| DIN EN 50125-1 | Railway applications, environmental conditions for operating resources, Part 1: Operating resources on railway vehicles 4.12 Vibrations and shocks |

| BWW GS 95024-3-1 | Electrical and electronic components in motor vehicles – Environmental requirements and testing M-01 Free Fall M-04 vibration test M-05 Mechanical shock M-06 Mechanical continuous shock |

| ISO 10326-2 | Mechanical vibrations – Laboratory methods for evaluating vibrations in vehicle seats – Part 2: Use on rail vehicles |

Solar Radiation

DIN EN IEC 60068-2-5, VDE 0468-2-5 | Environmental testing – Part 2-5: Tests – Test S: Simulated solar radiation at ground level and guidance for solar radiation testing and weathering (test Sa) |

| DIN 75220 | Ageing of automotive components in solar simulation units (Test D-IN1, D-IN2, Z-OUT, Z-IN1, Z-IN2) |

| MIL-STD 810 H | Method 505.7 Solar Radiation (Sunshine) |

VW 80000 | Electrical and electronic components in motor vehicles up to 3.5 t – General requirements, test conditions and tests K-17 solar exposures |

DIN EN 50125-1 | Railway applications, environmental conditions for operating resources, Part 1: Operating resources on railway vehicles 4.9 Solar radiation |

MBN 10306 | Electrical and electronic components in motor vehicles up to 3.5 t K-17 solar exposures |

BWW GS 95024-3-1 | Electrical and electronic components in motor vehicles up to 3.5 t K-17 solar exposures |

Corrosion Tests

DIN EN ISO 9227 | Corrosion tests in artificial atmospheres – Salt spray tests |

DIN EN IEC 60068-2-11, VDE 0468-2-11 | Environmental testing – Part 2-11: Tests; test Ka: Salt mist |

DIN EN IEC 60068-2-52, VDE 0468-2-52 | Environmental testing – Part 2-52: Tests – Test Kb: Salt mist, cyclic |

DIN EN ISO 6270-2 | Paints and varnishes – Determination of resistance to humidity – Part 2: Condensation (in-cabinet exposure with heated water reservoir), (Test CH, AHT, AT) |

DIN EN ISO 11997-1 | Paints and varnishes – Determination of resistance to cyclic corrosion conditions – Part 1: Wet (salt fog)/dry/humid, (Test KK, KFW, KTW) |

| VDA 621-415 | Cyclic corrosion test |

| VW PV 1210 | Cyclic corrosion test |

| DIN EN 61701 | Salt mist corrosion testing of photovoltaic (PV) modules |

| MIL-STD 810 H | Method 509.7 Salt Fog |

| RTCA DO160G | Environmental Conditions and Test Procedures for Airborne Equiment Section 14: Salt Spray |

DIN EN 61439-1, VDE 660-600-1, DIN EN 61439-5, VDE 660-600-5 | Low-voltage switchgear combinations Part 5: Switchgear assemblies in public power distribution networks, corrosion resistance testing |

DIN EN 61439-7, VDE 660-600-7 | Low-voltage switchgear combinations Part 7: Switchgear combinations for specific applications such as marinas, campsites, marketplaces, charging stations for electric vehicles |

IEC 60068-2-42 | Environmental testing – Part 2-42: Tests – Test Kc: Sulphur dioxide test for contacts and connections (SO2, Test Kc) |

IEC 60068-2-43 | Environmental testing – Part 2-43: Tests – Test Kd: Hydrogen sulphide test for contacts and connections, Corrosive Gas test/Hydrogen sulphide test (H2S, test Kd) |

DIN EN 60068-2-60, VDE 0468-2-60 | Environmental testing – Part 2-60: Tests – Test Ke: Flowing mixed gas corrosion test (4-gas test) |

ISO 6988 | Metallic and other non-organic coatings – Sulfur dioxide test with general condensation of moisture (Kesternich testing) |

| DIN 50018 | Testing in a saturated atmosphere in the presence of sulfur dioxide |

| VW 80000 | Electrical and electronic components in motor vehicles up to 3.5 t – General requirements, test conditions and tests K-06 Salt mist test with operation, outdoor components K-06 Salt mist test with operation, indoor components K-18 Corrosive Gas Test |

| VW PV 1209 | Attachments with a zinc or zinc alloy coating and aluminum components (e.g. heat exchanger, refrigerant pipe) – corrosion test) climate corrosion change test (not flexible accredited) |

| VW PV 1210 | Corrosion Test |

| DIN EN ISO 4628-1 | Coating materials – Assessment of coating damage – Assessment of the amount and size of damage and the intensity of changes in appearance – Part 1: General introduction and evaluation system |

| DIN EN ISO 4628-2 | Coating materials – Assessment of coating damage – Assessment of the amount and size of damage and the intensity of changes in appearance – Part 2: General introduction and evaluation system |

| DIN EN ISO 4628-3 | Coating materials – Assessment of coating damage – Assessment of the amount and size of damage and the intensity of changes in appearance – Part 3: Assessment of the degree of rust |

| DIN EN ISO 4628-4 | Coating materials – Assessment of coating damage – Assessment of the amount and size of damage and the intensity of changes in appearance – Part 4: Assessment of the degree of cracking |

| DIN EN ISO 4628-5 | Coating materials – Assessment of coating damage – Assessment of the amount and size of damage and the intensity of changes in appearance – Part 5: Assessment of the degree of peeling |

| DIN EN ISO 4628-6 | Coating materials – Assessment of coating damage – Assessment of the amount and size of damage and the intensity of changes in appearance – Part 6: Assessment of the degree of chalking by the adhesive tape method |

| DIN EN ISO 4628-8 | Coating materials – Assessment of coating damage – Assessment of the amount and size of damage and the intensity of changes in appearance – Part 8: Assessment of debonding and corrosion from a scratch |

| ISO 14993 | Corrosion of Metals and Alloys – Accelerated corrosion testing including cyclic exposure to salt spray, “dry” “wet” conditions |

| DIN ISO 9022-4 | Optics and Photonics – Environmental Testing Methods Part 4: Salt Spray |

| DIN ISO 9022-20 | Optics and Photonics – Environmental Test Methods Part 20: Moist atmosphere containing sulfur dioxide or hydrogen sulfide |

| DIN EN ISO 12944-6 | Coating materials – Corrosion protection of steel structures through coating systems – Part 6: Laboratory tests for the evaluation of coating systems |

| SAE J2334 | Laboratory Cyclic Corrosion Test (Verfahren c: air Atomized Fog Method) |

| DIN EN ISO 22479 | Corrosion of metals and alloys Testing with sulfur dioxide in a moist atmosphere (fixed gas volume method |

| DIN EN ISO 10062 | Corrosion tests in an artificial atmosphere with very low concentrations of harmful gas(es) Electrical and electronic components in motor vehicles – Environmental requirements and tests K-06 Salt spray test with operation, outdoor area K-07 Salt spray test with operation, interior K-18 harmful gas testing |

| BWW GS 95024-3-1 | Electrical and electronic components in motor vehicles – Environmental requirements and tests K-06 Salt spray test with operation, outdoor area K-07 Salt spray test with operation, interior K-18 harmful gas testing |

| ASTM B 117 | Standard Practice for Operating Salt Spray (Fog) Apparatus |

IP Tests

DIN EN 60529, VDE 0470-1 | Degrees of protection provided by enclosures (IP Code). Protected against access to hazardous parts IP5X: Dust-protected IP6X: Dust-tight IPX1: Protected against vertical water drips IPX2: Protected against water drips (15° inclination) IPX3: Protected against water spray IPX4: Protected against splash water IPX5: Protected against water jets IPX6: Protected against powerful water jets IPX7: Protected against water (temporary immersion) IPX8: Protected against water (continous immersion) IPX9: Protected against high pressure and high temperature jets |

| ISO 20653 | Road vehicles – Degrees of protection IPX4K: Protected against splash water with increased pressure IPX6K: Protected against strong high-velocity water with increased pressure IPX9K: Protected against high-pressure/steam-jet cleaning IP5KX: Dust-protected IP6KX: Dust-tight |

| DIN EN 60598-1, VDE 0711-1 | Luminaires – Part 1: General requirements and tests, Section 9 (Resistance to dust, solid foreign bodies and water) |

| DIN EN 60034-5, VDE 0530-5 | Rotating electrical machines – Part 5: Degrees of protection based on the overall design of rotating electrical machines (IP code) – Classification |

IK Tests

| DIN EN 62271-1, VDE 0671-1 | Degrees of protection provided by enclosures for electrical equipment against external mechanical impacts (IK code) IK1, IK2, IK3, IK4, IK5, IK6, IK7, IK8, IK9, IK10 |

| DIN EN 60068-2-75, VDE 0468-2-75 | Environmental influences – Part 2-75: Tests – Test Eh: Hammer tests |

| DIN EN 62262, VDE 0470-100 | Types of protection provided by housings for electrical equipment (equipment) against external mechanical stress (IK code) |

Dust Tests

| RTCA DO160G | Environmental Conditions and Test Procedures for Airborne Equiment Section 12: Sand and Dust |

| DIN EN 60529, VDE 0470-1 | Degrees of protection through housing (IP code) |

| DIN EN 60068-2-68, VDE 0468-2-68 | Environmental testing – Part 2-68: Tests; Test L: Dust and sand |

| VW 80000 | Electrical and electronic components in motor vehicles up to 3.5 t – General requirements, test conditions and tests M-03 dust test |

MBN 10306 | Electrical and electronic components in motor vehicles – Environmental requirements and tests M-03 dust test |

BWW GS 95024-3-1 | Elektrische und elektronische Komponenten in Kraftfahrzeugen – Umweltanforderungen und Prüfungen M-03 Staubprüfung |

Water Tests

| DIN EN 60529, VDE 0470-1 | Degrees of protection through housing (IP code) |

| DIN EN 60068-2-18, VDE 0468-2-18 | Environmental influences – Part 2-18: Test procedures – Test R and Guide: Water test |

| VW 80000 | Electrical and electronic components in motor vehicles up to 3.5 t – General requirements, test conditions and tests K-10 Water protection – IPX0 to IPX6K K-11High pressure/steam jet cleaning |

| MIL-STD 810 H | Methode 506.6 Rain & Blowing Rain |

| MIL-STD 810 H | Methode 512.6 Immersion |

| MBN 10306 | Electrical and electronic components in motor vehicles – Environmental requirements and tests K-10 water protection – IPX0 to IPX6K K-11 high pressure/steam jet cleaning |

| BWW GS 95024-3-1 | Electrical and electronic components in motor vehicles – Environmental requirements and tests K-10 water protection – IPX0 to IPX6K K-11 high pressure/steam jet cleaning |

| RTCA DO-160G | Enviromantel Conditions and Test Procedures for Airbone Equipment Section 10: Waterproofness |

Sorry, nothing found.

Request & Contact

Contact us now! We will be pleased to support you, send you information material

and provide you with a quote for your enquiry.

telephone: +49 (0)3302 49982 50

e-maill: umwelt@rst-labs.de